WM-200 Anglemaster: Consistent Sharpening Angles

Getting your sharpening angle right matters more than most people realize. The difference between a dull edge and a sharp one often isn't the stone or the steel. It is whether you're grinding at 15° or 20°, whether you're compensating for wear, and whether you can repeat that angle reliably. The WM-200 Anglemaster addresses this head-on: a precision angle setting tool designed to measure, set, and verify sharpening angles from 10° to 75° across grinding stones that range from 150mm (6 inches) to 250mm (10 inches) in diameter.[1][2]

This isn't glamorous gear. It's a plastic-and-magnet tool that solves a specific, quantifiable problem. For users chasing repeatability (whether you're processing field tinder in sleet, prepping mise en place before service, or maintaining your EDC folder), angle consistency is where precision lives.

Why Does Sharpening Angle Matter?

What happens when your angle drifts?

A knife sharpened at 15° per side cuts differently than one at 20°. The 15° edge is sharper initially but wears faster and is more fragile under stress. At 20°, you sacrifice some initial bite for durability. Neither is wrong, but inconsistency is. If you sharpen at 15° one month and 20° the next, your edge geometry shifts, steel removes unevenly, and the blade feels unpredictable.

Worse, you can't diagnose problems. Is the edge failing because the steel is wrong, your technique is sloppy, or the angle mismatch is compromising durability? Without a baseline, you're guessing.

How stone wear complicates the problem

When you use a grinding stone for weeks or months, its diameter shrinks. A stone that started at 250mm drops to 230mm, then 200mm. If you don't adjust your angle-setting jig to account for that wear, your edge angle gradually changes without you noticing, and your results get inconsistent.[1] This is where field users and backcountry sharpeners hit a wall. You can't flatten a stone at base camp, and you can't eyeball stone wear under a headlamp. For stone care strategies and wear rates, see our water vs oil vs diamond stone maintenance comparison.

How Does the WM-200 Solve Angle Consistency?

Two core functions

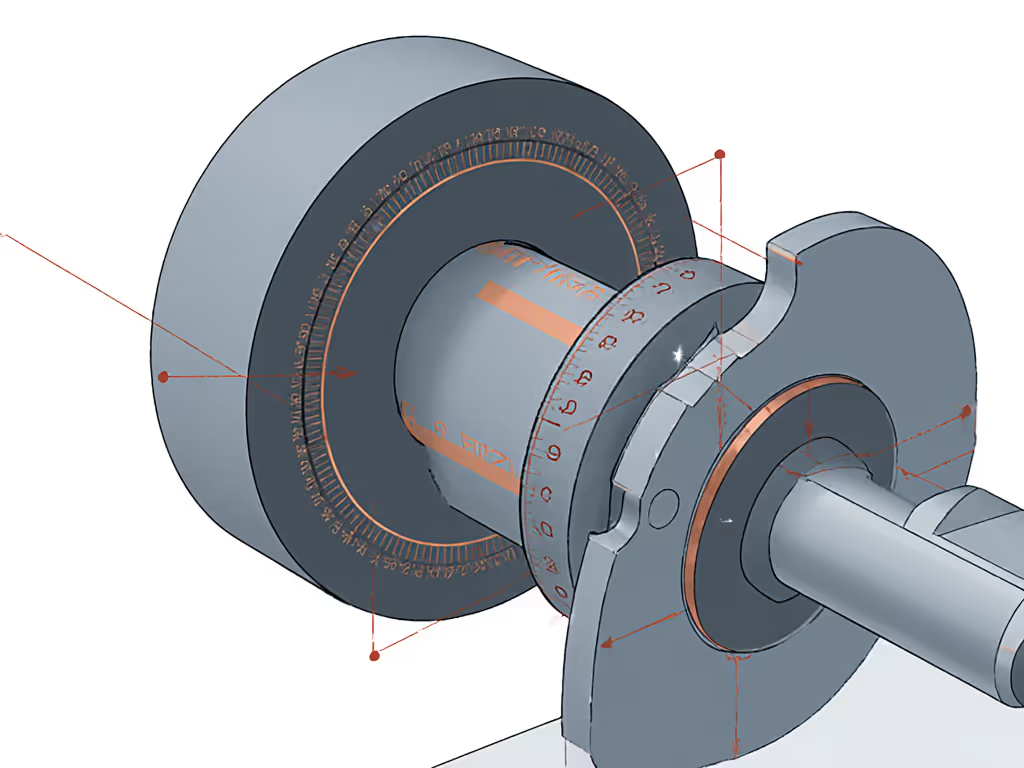

The WM-200 Anglemaster has a straightforward design with two magnetic feet and a series of measurement grooves cut into its edge.[2][3] It performs two functions:

-

Set angles before sharpening: Place it against your grindstone, adjust your jig until the tool's reference face aligns with the stone, and you've locked in your target angle.[3] You can set any angle from 10° to 75°, enough range for kitchen knives, chisels, axes, and specialty grinds.

-

Measure existing bevels: Flip the tool into measuring mode and place it against a blade's bevel. The grooves on the Anglemaster's edge let you read what angle you've already ground into the steel, so you can verify consistency or diagnose drift.[3]

Compensation for wear

The tool includes a diameter compensator that accounts for stone wear.[3] After weeks of use, your grindstone has shrunk. The Anglemaster lets you dial in the current diameter, and the tool adjusts its reference geometry automatically. You set the same angle on a worn stone that you'd set on a fresh one (no math, no guessing).

Edges that survive rain, grit, and cold hands matter most. Without compensation, a worn stone forces you to either accept angle drift or spend time at base camp recalibrating. The compensator collapses that problem.

Magnet mounting for field and workshop use

The dual magnets allow the tool to stick directly to the machine housing on compatible Tormek models (T-8, T-7, T-4, and newer).[2] If you're considering a full wet grinder setup, read our Tormek T-8 wet grinding system review. This keeps it close and accessible. You're not hunting for it, and it's not rolling off a wet stump or disappearing in camp clutter. On workshop benches, that proximity matters. You set an angle, sharpen a blade, and can re-measure in seconds without repositioning or digging through a kit.

FAQ: Common Questions About Angle Consistency

What angle should I use for different knives?

There is no universal answer: it depends on steel hardness, use case, and your tolerance for maintenance:

- Kitchen knives (stainless, 56-60 HRC): 15°-20° per side is typical. Softer steels like VG-10 or similar can hold sharper angles; harder super-steels (M390, S35VN) benefit from 18°-22° for durability. For details on abrasives and techniques that excel on these alloys, see our sharpening supersteels guide.

- EDC folders (hardened tool steel, 60-62 HRC): 18°-25° per side. Sharper edges dull faster in pocket use; steeper angles survive abuse.

- Axes, cleavers, and tools (50-55 HRC): 25°-30° per side. Lower hardness and heavy use demand robust geometry.

- Chisels, plane irons (60-62 HRC): 25°-30° per side, often with a micro-bevel at 2°-3° steeper to reinforce the apex.

The Anglemaster's 10°-75° range covers all these. The key is picking one and staying consistent. If you sharpen your kitchen knife at 18° and your EDC at 20°, don't swap them unknowingly. Angle drift is worse than a non-optimal starting angle.

How tight should angle tolerance be?

Variance of ±2° per side is acceptable for most users; ±1° is excellent. Lab data confirms this: blades sharpened within ±1° show consistent performance across cuts and durability tests. Beyond ±3° variance, edge geometry becomes unreliable; it cuts differently each session, and steel removes unevenly.[2]

The Anglemaster's pinpoint accuracy design keeps you within ±1° if you use the tool consistently and account for stone wear.[1] That's the boundary between field-ready reliability and frustration.

Does angle matter more than stone choice?

Yes, within reason. A mid-tier stone sharpened at a locked, correct angle outperforms a premium stone ground at a drifting angle. Repeatability is the floor. Stone quality, grit progression, and maintenance are the next layers. Angle is foundational; everything else builds on it.

Can I use the WM-200 with portable or whetstones?

The Anglemaster is designed for grinding wheels (powered wet grinders, primarily). It won't work directly on flat whetstones because whetstones don't have a fixed diameter reference (they flatten over time), but their geometry is different from a rotating stone.[2] However, the principle of angle consistency transfers: on whetstones, use a guide jig or angle blocks, mark your starting angle, and check it every few sessions.

Integrating Angle Measurement into Your Sharpening Workflow

Before your first session

Measure your grindstone diameter. Record it. Set your target angle using the Anglemaster, and lock your jig. Sharpen a test blade (a cheap kitchen knife or utility blade) and verify the angle afterward. This baseline is crucial.

During regular sharpening

Before each session, glance at your grindstone. If it's obviously worn (visibly smaller), update the diameter setting on the Anglemaster. Reset your jig. Sharpen. Re-measure the blade's bevel to confirm the angle held.

This adds roughly 60 seconds per session. It's not a rain test you run every time (it's a quick verification that your setup hasn't drifted).

Three-minute micro-bevel touch-up in the field

When you're backcountry or in a remote kitchen and your edge has started to roll, a micro-bevel refresh works: reset your angle 2°-3° steeper than your primary bevel, and grind a thin edge at that steeper angle for 30-60 seconds per side. This reinforces the apex without removing much steel. The Anglemaster lets you dial in that steeper angle in seconds, so your micro-bevel is repeatable, not guesswork.

I've done this on a sleet-soaked ridge with a pocket sharpener and a flask as a makeshift backing stone, and the repeatability came from knowing exactly what angle I'd locked in before the weather turned. Without angle verification, you're hoping and grinding.

Maintenance cadence

Every 2-4 weeks (depending on use), check your stone diameter. Monthly, measure a blade's existing angle and compare it to your target. If variance exceeds ±1.5°, re-flatten your stone or adjust your jig. This disciplined approach prevents the slow drift that derails consistency.

Final Verdict

The WM-200 Anglemaster is not a luxury. It's a precision angle measurement tool that collapses a major source of unreliability in sharpening: angle drift due to stone wear and setup creep. For home cooks chasing repeatable edges on kitchen knives, EDC users maintaining field blades, or anyone frustrated by inconsistent results, this tool delivers a measurable return: edges within ±1° tolerance, repeatability across sessions, and the confidence that your sharpening baseline is solid.

The cost is low (typically $35-40). The learning curve is shallow: measure, set, lock, sharpen, verify. The payoff is significant: you stop guessing, your results stabilize, and expensive blades last longer because they're sharpened correctly, consistently, and without the wear spikes that come from angle drift.

If you're serious about sharp tools as a reflection of skill and care (whether in the kitchen, the shop, or the backcountry), this is a gap-filler. It won't sharpen a blade for you. It will ensure every session starts from a repeatable, verified baseline. That's the difference between gear you trust and weight you carry.